CNC Machine Definition, Need, Working, Advantages, Disadvantages And It’s Application

Table of Contents

Table of Contents

“CNC Machine Definition, Need, Working, Advantages, Disadvantages And It's Application”

Hello Friend In This Blog We Have To Cover Of All The Topic To Related To CNC Machine In This Article You Have To Knowledge About

Let's Start The Article With

What is CNC Machine?

● Conventionally, an operator decides and adjusts various machines parameters like feed, depth of cut, rpm etc. depending on the type of job, and controls the slide movements by hand. In a NC Machine functions and slide movements are controlled by motors using a set of instructions called a program.

● Numerical Control is defined as the form of programmable automation, in which the process is controlled by numbers, letters and symbols. In case of machine tools this programmable automation is used for the operation of machines. In initial years of NC, punched tapes/cards were used for feeding the instructions to the machine tools via control unit. For every new type job, the program of instructions is to be changed.

Computer Numeric Control (CNC):

● In this machines programs are fed in the computer which is used to control the operations of the machine. which a computer is used to control all the machine movements as per program stored in computer memory.”

Need Of The CNC Machine

Modern precision manufacturing demands extreme dimensional accuracy and surface finish. Such performance is very difficult to achieve manually, if not impossible, even with expert operators. In cases where it is possible, it takes much higher time due to the need for frequent dimensional measurement to prevent overcutting. It is thus obvious that automated motion control would replace manual “hand wheel” control in modern manufacturing.

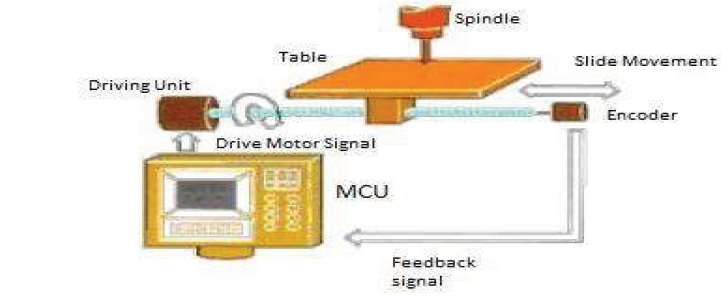

A modern CNC machine works in a closed loop system.

There are mainly 6 basic elements of the machine:

- Input Devices: These are the devices which are used to input the part program in this machine. Commonly pen drive, card, LAN, or manual input is used for inserting the program.

- Machine Control Unit (MCU): It is the heart of the machine. It performs all the controlling action of the machine. The various functions performed by the MCU are:

- It reads the coded instructions fed into it.

- It decodes the coded instructions.

- It implements interpolation (linear, circular, and helical) to generate axis motion commands.

- It feeds the axis motion commands to the amplifier circuits for driving the axis mechanisms.

- It receives the feedback signals of position and speed for each drive axis.

- It implements the auxiliary control functions such as coolant or spindle on/off and tool change.

- Receives feedback from the encoder.

- Driving Unit: The driving system of the machine consists of amplifier circuits, drive motors, and ball lead screw. The MCU feeds the signals (i.e., of position and speed) of each axis to the amplifier circuits. The control signals are then augmented (increased) to actuate the drive motors. The actuated drive motors rotate the ball lead screw to position the machine table.

- Machine Tool: This machine tool always has a slide table and a spindle to control the position and speed. The machine table is controlled in the X and Y-axis direction, and the spindle is controlled in the Z-axis direction.

- Feedback Device: This system consists of transducers that act like sensors. It is also called a measuring system. It contains position and speed transducers that continuously monitor the position and speed of the cutting tool located at any instant. The MCU receives the difference between the reference signals and feedback signals to generate the signals from these transducers, and it uses the control signals for correcting the position and speed errors.

- Output Device: A monitor is used to display the programs, commands, and other useful data of the machine.

Advantages of CNC Machine

- Improves machining accuracy

- Enables complex tasks and detailing

- Creates flexibility in manufacturing

- Increases safety

- Boosts production volume

- Reduces setup-changeover time, etc.

- Operators can easily make changes and improvements that reduce delay time

- Automation can be easily implemented, leading to low human interaction

- Consistency in the accurate parts produced is also high

Disadvantages of CNC Machine

- Cost of a this machine and its parts is high.

- Parts of a this machine are costly, and its maintenance cost is quite high.

- It requires sophisticated tooling.

- A skilled programmer is required to make complex part programs.

Applications

- The applications of CNC include both for machine tool as well as non-machine tool areas.

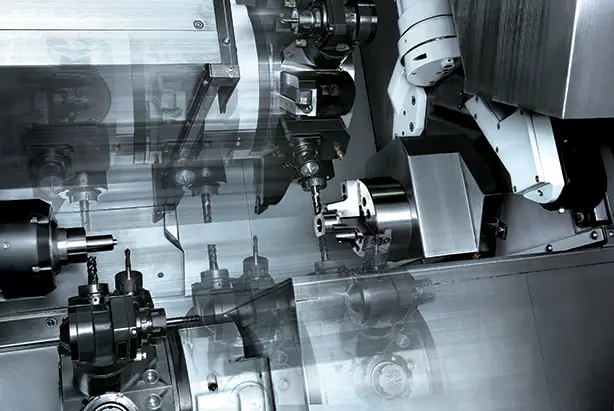

- In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet bending machine, etc.

- Highly automated machine tools such as turning center and machining center which change the cutting tools automatically under CNC control have been developed.

- In the non-machine tool category, CNC applications include welding machines (arc and resistance), coordinate measuring machine, electronic assembly, tape laying, and filament winding machines for composites, etc.

So Stay Connected With Us. Be Prepared With MECHSTECH.

Explore More:

- Types Of Cutting Tool Materials

- Tool Wear, Tool Life & Machinability

- Parts of Lathe Machine

- Research Paper: Fire Extinguisher Drone

So, Stay Connected With Us. Be Prepared With MECHSTECH.

sdvfvsdfe

Nice post for me and It is a very different blog than the usual ones I visit. From this post , I get more knowledge and I read a lot of interesting content here. Thanks for sharing a knowledgeable post. CNC milling machine

Many congratulations that you could manage to write on this sensible issue. I am taking the helping tips and hope it will be useful for others too. Thank you so much. Custom CNC Micromachining Service From Valley Design.

Your take on the subject is wonderful. I agree with your opinion. Hope to read more on this topic to increase my knowledge in this field. Colored Optical Glass Filters.

I admire this article for the well-researched content and excellent wording. Read more info about Heavy Machinery Supplier in Dubai. I got so involved in this material that I couldn’t stop reading. I am impressed with your work and skill. Thank you so much.

This is something I ‘ve been searching for for a while.I’m thankful to you for writing this article. ALN CNC Machining Services By Valley Design.

I found decent information in your article. I am impressed with how nicely you described this subject, It is a gainful article for us. Thanks for share it. Undercarriage Dozer Parts online

Nice info, I am very thankful to you for sharing this important knowledge. This information is helpful for everyone. Read more info about Heavy Machinery Supplier in Dubai So please always share this kind of information. Thanks.

You have provided valuable data for us. It is great and informative for everyone. Read more info about Machine Tool Suppliers Company in Dubai Keep posting always. I am very thankful to you.

The information you've provided about Linear Motor Magnetics is quite beneficial. I'm fascinated by the intricacies, and it's also an important piece for us. Thank you for continuing to provide this type of information.

You have published an extraordinary article here about magnetic shaft coupling. It is genuinely beneficial info for us.

I generally check this kind of article and I found your article which is related to my interest. Genuinely it is good and instructive information about Sheet Metal Laser Cutting. Thankful to you for sharing an article like this.

Clearly, It is an engaging article for us which you have provided here about Heavy Machinery Supplier in Dubai This is a great resource to enhance knowledge about it. Thank you.

You are sharing a piece of nice information here about HDPE tubes. The information you have provided is genuinely instructive and significant for us. Thanks for sharing an article like this.

Excellent post. I really enjoy reading and also appreciate your work.shredding machinery This concept is a good way to enhance knowledge. Keep sharing this kind of articles, Thank you.

Your blog held my interest right to the very end, which is not always an easy thing to do!!

ceramic cnc machining services

I recently came upon your blog and wanted to express how much I liked reading your postings. I'm hoping you'll write again soon. Thank you very much for the excellent information. test and tag services Melbourne

Thanks for sharing such brilliant ideas I really like your blog about fire extinguisher service for us..

Thank you so much for the sharing. All contents were expressed in a clear n simplified manner n it was meaningful too. You are a marvelous writer. Good work! Lapped Ceramic Substrates From Valley Design.

Hi friends, good pieces of writing and very helpful articles, I am truly enjoying these. I just want to Share <a href="https://mfgempire.com/cnc-precision-machining-technology/

>Precision Machining Technology

</a>

I felt very happy while reading this site. This was really very informative site for me. I really liked it. This was really a cordial post. Thanks a lot!. Edge Rounding Deburring Machines.

Hi friends, good pieces of writing and very helpful articles, I am truly enjoying these. I just want to Share about our Building management systems services Thanks

This blog has turned me into a follower. I’m very impressed by your work and I’m adding you to my list of favorites. Custom CNC Micromachining Services.

This was a fantastically creative article. Thank you! Building management systems

You’ve provided great information in your blog. Many thanks for sharing the information in your blog. Glass CNC Machining Service From Valley Design.

You’re an excellent blogger. I’m very impressed by your work and will recommend your tips to everyone in my circle so that they can also benefit from this information. Colored Optical Glass Filters From Valley Design.

I’d like to thank you for writing on this topic. The information you provided was very useful. I will visit again in the near future.

fused silica cnc machining

You have given us the opportunity to understand the topic. You have a very clear view over the subjects which make it very simple to comprehend. Thank you so much.

lapping and polishing services

Thanks for helping us understand this topic. You have written it in a way that makes it very simple to understand. Thank you so much. Polished Silicon Wafers From Valley Design.

Your take on the subject is wonderful. I agree with your opinion. Hope to read more on this topic to increase my knowledge in this field. Glass Lapping and Polishing Services for All Materials.

You’re certainly a great writer. Your post provided me with many helpful pieces of information. Custom Optical Coatings and Thin Film Coatings.

"I've been struggling to find the right water pump for my greenhouse, so I'm grateful for the advice you provided in this post. I'm definitely going to take your recommendations into consideration when making my next purchase. Thanks again!"